Wellhead Maintenance Things You Should Know

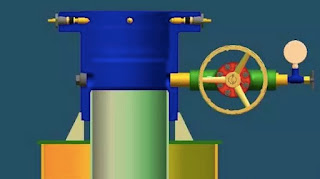

The maintenance of the wellhead xmas tree.

The maintenance and maintenance of the tree is: keep the equipment clean, no oil, no oil, no rust, no pine.

Moving, intact parts and parts switch are flexible and easy to use. To domestic CY250 tree as an example, the parts are: cross, left and right sides casing pipe gate, tubing head, tubing spool, total gate, about production valve, test gate or paraffin gate (blowout preventer), tubing hanging roof of silk, clamp, steel ring, and other accessories.

1. The failure and maintenance of gate type 250 gate are easy to occur.

(1) replace gate thrust bearing and copper sleeve.

Open the gate, remove the handwheel pressure cap, remove the handwheel and handwheel key, remove the bearing gland, remove the copper sleeve from the screw thread, remove the old bearing, and replace the new bearing with the butter. Put the copper suit on the screw, the screw thread into the gate big gland, install the bearing gland, hold the handwheel and the handwheel and the handwheel press cap, wipe the dirt.

(2) O type sealing ring (gate) to replace the gate screw

As in the field replacement, no control parts of the valve should be replaced after kill again, if it is can control parts should pour the process behind the blow-down removable, with 900 mm or 1200 mm pipe wrench removing the gate big gland, along with the ram is put forward. Remove the ram and bring out the screw (remove the handwheel and copper sleeve bearings first) and remove the old sealing ring. Replace the new type sealing ring; Hang the gate after confirmation. Push the gate groove into the valve body, tighten the cover, and close the gate until it is tight. After the test pressure is qualified, the original process is restored.

2. Matters needing attention in the use of gate type 250 gate valves.

Avoid the gate oil to wear the bad bearings, should be refueled regularly.

The switch gate should be opened or closed after death.

The water in the pipeline should be released during the winter shut-in, in case of the freezing of the gate and the steps on the gate.

If you find that the gate is frozen, don't open it, use hot water to warm it up and then open it with a hand hammer to gently stroke the lower part of the gate.

Fault check and maintenance of seal ring between tubing head and tree.

1. Main seal and secondary seal of tubing hanger.

The main seal is sealed by the combination of "O" ring and square ring (see figure 3). Under the condition that the main and secondary seal is normal, the sealing ring between the two flanges is not withstanding the pressure of the medium. If the primary seal leakage, tighten the top silk, inspire primary seal of square seal ring expansion, at the same time through the tree on the adapter flange pressure hole injection of a large number of leak sealing grease compensation gap.

If the secondary seal leaks, it can only be injected with a large amount of sealing grease to compensate for the leakage gap through the pressure hole in the tree variable diameter flange.

2. Leakage from the top of the tubing.

If a leak occurs on the top of the tubing, tighten the top wire packing gland, press the top wire packing further, and activate the packing expansion to achieve the purpose of sealing.

3. Leakage of pressure hole thread.

If it is a leak of the test thread, the main seal or the secondary seal leakage of the tubing hanger is indicated, as well as the leakage of the main and secondary seal, which can be processed through the first article. Leakage of pressure hole thread can be solved by tightening the grease valve thread on the pressure test hole.

4. Other questions

When using the method of article 1, 2, 3, had still not solve the junctions between the tubing head and Christmas tree seal ring leak problem, should timely report to the mining of oil and gas, after the security technology agreement and service contract, used for pressure switch valve technology under the tubing plug for repair and replace the seal ring.

5. Maintenance of connection between tubing head and oil tree.

The connection between the tubing head and the tree is subjected to extremely high pressure and is prone to leakage, so we must maintain and maintain it regularly in our daily production process.

First check whether the flange nut of the connection is loose.

Every nut must be checked. If there is a loose phenomenon, it must be tightened by hand to avoid leakage.

Check whether the cap is loose.

Wire in daily production process, the top pressure cap and wire should also regularly check, to avoid the loose caused leakage phenomenon, especially new production Wells, the production must be used to move the hand tighten again a month later silk gland cap and top silk.

To buy oilfield x-mas tree, welcome to contact http://www.rtpetro.com/.

The maintenance and maintenance of the tree is: keep the equipment clean, no oil, no oil, no rust, no pine.

Moving, intact parts and parts switch are flexible and easy to use. To domestic CY250 tree as an example, the parts are: cross, left and right sides casing pipe gate, tubing head, tubing spool, total gate, about production valve, test gate or paraffin gate (blowout preventer), tubing hanging roof of silk, clamp, steel ring, and other accessories.

1. The failure and maintenance of gate type 250 gate are easy to occur.

(1) replace gate thrust bearing and copper sleeve.

Open the gate, remove the handwheel pressure cap, remove the handwheel and handwheel key, remove the bearing gland, remove the copper sleeve from the screw thread, remove the old bearing, and replace the new bearing with the butter. Put the copper suit on the screw, the screw thread into the gate big gland, install the bearing gland, hold the handwheel and the handwheel and the handwheel press cap, wipe the dirt.

(2) O type sealing ring (gate) to replace the gate screw

As in the field replacement, no control parts of the valve should be replaced after kill again, if it is can control parts should pour the process behind the blow-down removable, with 900 mm or 1200 mm pipe wrench removing the gate big gland, along with the ram is put forward. Remove the ram and bring out the screw (remove the handwheel and copper sleeve bearings first) and remove the old sealing ring. Replace the new type sealing ring; Hang the gate after confirmation. Push the gate groove into the valve body, tighten the cover, and close the gate until it is tight. After the test pressure is qualified, the original process is restored.

2. Matters needing attention in the use of gate type 250 gate valves.

Avoid the gate oil to wear the bad bearings, should be refueled regularly.

The switch gate should be opened or closed after death.

The water in the pipeline should be released during the winter shut-in, in case of the freezing of the gate and the steps on the gate.

If you find that the gate is frozen, don't open it, use hot water to warm it up and then open it with a hand hammer to gently stroke the lower part of the gate.

Fault check and maintenance of seal ring between tubing head and tree.

1. Main seal and secondary seal of tubing hanger.

The main seal is sealed by the combination of "O" ring and square ring (see figure 3). Under the condition that the main and secondary seal is normal, the sealing ring between the two flanges is not withstanding the pressure of the medium. If the primary seal leakage, tighten the top silk, inspire primary seal of square seal ring expansion, at the same time through the tree on the adapter flange pressure hole injection of a large number of leak sealing grease compensation gap.

If the secondary seal leaks, it can only be injected with a large amount of sealing grease to compensate for the leakage gap through the pressure hole in the tree variable diameter flange.

2. Leakage from the top of the tubing.

If a leak occurs on the top of the tubing, tighten the top wire packing gland, press the top wire packing further, and activate the packing expansion to achieve the purpose of sealing.

3. Leakage of pressure hole thread.

If it is a leak of the test thread, the main seal or the secondary seal leakage of the tubing hanger is indicated, as well as the leakage of the main and secondary seal, which can be processed through the first article. Leakage of pressure hole thread can be solved by tightening the grease valve thread on the pressure test hole.

4. Other questions

When using the method of article 1, 2, 3, had still not solve the junctions between the tubing head and Christmas tree seal ring leak problem, should timely report to the mining of oil and gas, after the security technology agreement and service contract, used for pressure switch valve technology under the tubing plug for repair and replace the seal ring.

5. Maintenance of connection between tubing head and oil tree.

The connection between the tubing head and the tree is subjected to extremely high pressure and is prone to leakage, so we must maintain and maintain it regularly in our daily production process.

First check whether the flange nut of the connection is loose.

Every nut must be checked. If there is a loose phenomenon, it must be tightened by hand to avoid leakage.

Check whether the cap is loose.

Wire in daily production process, the top pressure cap and wire should also regularly check, to avoid the loose caused leakage phenomenon, especially new production Wells, the production must be used to move the hand tighten again a month later silk gland cap and top silk.

To buy oilfield x-mas tree, welcome to contact http://www.rtpetro.com/.

Comments

Post a Comment