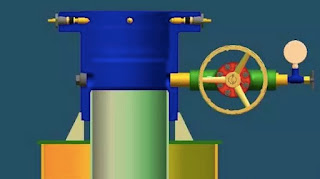

Gas Extraction Wellhead installation, Protection and Maintenance

1. Inspection and maintenance of wellhead pulley

2. Check and maintain the tension meter

3. Inspection and maintenance of magnetic markers

4. Inspection and maintenance of the scraper wellhead assembly

5. Inspection and maintenance of collector rings

6. Check and maintain the logging depth measurement device

The gas wellhead device should be maintained at least half a year, for a hydrogen sulphide content of more than 3000mg/m3 or more than 5m3/d of gas wellhead valve should be maintained every quarter.

Maintenance content should include more than 2 times valve switch activities, butter filling, sealing check, accessories maintenance, gas extraction wellhead clean, compressed anti-corrosive paint repair, heat preservation, etc., to ensure that the gas extraction wellhead complete, no rust, no leakage, flexible valve switch, no leakage, normal use of attached parts, anti-corrosion insulation in good condition.

Gas extraction wellhead maintenance should fill in the form, which mainly contains the well number, gas extraction tree and accessories manufacturers, specifications, maintenance time, maintenance personnel, maintenance content, problems, and the recorder etc.

(1) Reach the well field to observe the terrain, set the winch and lay a good cover wood;

(2) Move the wellhead pulley, pulley noose, pulley bracket, tension gauge, nozzle, wellhead joint, grease pump, grease pump pipeline, hand pressure pump and pipelines, wellhead tools and wellhead connecting wiring to the wellhead location;

(3) Starting the winch engine, putting down the nozzle, the cable head and the appropriate length cable, and placing the cable into the "∞" shape into the safe position of the well field;

(4) Put the pulley rope around under the tree flange, put one end of the noose through the other and locked, the other end locked to the spring pin in the ground pulley;

(5) Remove the bolt at one end of the pulley side splint, open the side plate of the pulley, put the cable into the pulley groove, then close the splint and insert the spring pin;

(6) To remove the blowout preventer before the nozzle, pull the cable head and through the nozzle, at the same time, wipe the other end of the BOP cable, to prevent the mud sand into the blowout preventer, to connect the BOP and the nozzle, and connect the required instrument to the cable head, the power check after normal pull into the nozzle, the blowout-proof pipe cable in need of at least 0.5M;

(7) The hand pressure pump pipe line is connected to the pressure pump;

(8) Connect the liquid flow pipeline;

(9) Connect the grease pump and line, as well as the gas source line of grease pump;

(10) The noose of the bop nozzle is properly connected;(11) Open the side plate of the sky pulley and place the side plate after cable;

(12) The tension gauge is connected to the sky pulley;

(13) Put the tension gauge rings and bop sling together hanging to the crane hook;

(14) Brush the thread of the movable joint with a wire brush;

(15) Command the crane to slowly lift the blowout preventer system, sit to the wellhead joint tightened well;

(16) Conductor of the cable from the well field to the winch, loose the hand pressure pump, open the oil tree clear fat valve;

(17) Check whether the pulley and cable operation are normal and solve the problem if any mistake.

2. Check and maintain the tension meter

3. Inspection and maintenance of magnetic markers

4. Inspection and maintenance of the scraper wellhead assembly

5. Inspection and maintenance of collector rings

6. Check and maintain the logging depth measurement device

The gas wellhead device should be maintained at least half a year, for a hydrogen sulphide content of more than 3000mg/m3 or more than 5m3/d of gas wellhead valve should be maintained every quarter.

Maintenance content should include more than 2 times valve switch activities, butter filling, sealing check, accessories maintenance, gas extraction wellhead clean, compressed anti-corrosive paint repair, heat preservation, etc., to ensure that the gas extraction wellhead complete, no rust, no leakage, flexible valve switch, no leakage, normal use of attached parts, anti-corrosion insulation in good condition.

Gas extraction wellhead maintenance should fill in the form, which mainly contains the well number, gas extraction tree and accessories manufacturers, specifications, maintenance time, maintenance personnel, maintenance content, problems, and the recorder etc.

Installation of Gas Wellhead Extraction Equipment

(2) Move the wellhead pulley, pulley noose, pulley bracket, tension gauge, nozzle, wellhead joint, grease pump, grease pump pipeline, hand pressure pump and pipelines, wellhead tools and wellhead connecting wiring to the wellhead location;

(3) Starting the winch engine, putting down the nozzle, the cable head and the appropriate length cable, and placing the cable into the "∞" shape into the safe position of the well field;

(4) Put the pulley rope around under the tree flange, put one end of the noose through the other and locked, the other end locked to the spring pin in the ground pulley;

(5) Remove the bolt at one end of the pulley side splint, open the side plate of the pulley, put the cable into the pulley groove, then close the splint and insert the spring pin;

(6) To remove the blowout preventer before the nozzle, pull the cable head and through the nozzle, at the same time, wipe the other end of the BOP cable, to prevent the mud sand into the blowout preventer, to connect the BOP and the nozzle, and connect the required instrument to the cable head, the power check after normal pull into the nozzle, the blowout-proof pipe cable in need of at least 0.5M;

(7) The hand pressure pump pipe line is connected to the pressure pump;

(8) Connect the liquid flow pipeline;

(9) Connect the grease pump and line, as well as the gas source line of grease pump;

(10) The noose of the bop nozzle is properly connected;(11) Open the side plate of the sky pulley and place the side plate after cable;

(12) The tension gauge is connected to the sky pulley;

(13) Put the tension gauge rings and bop sling together hanging to the crane hook;

(14) Brush the thread of the movable joint with a wire brush;

(15) Command the crane to slowly lift the blowout preventer system, sit to the wellhead joint tightened well;

(16) Conductor of the cable from the well field to the winch, loose the hand pressure pump, open the oil tree clear fat valve;

(17) Check whether the pulley and cable operation are normal and solve the problem if any mistake.

R&tT group offers wellhead assembly for oil and gas extraction for worldwide customers. Welcome to discuss details!

Comments

Post a Comment