Classification of casing head

1. According to the number of casing layers.

The number of casing layers can be divided into: single-stage casing head, double-stage casing head and three-stage casing head; The single-stage casing head is usually used in low-pressure shallow stratum production well; The double-stage casing head is suitable for the area with more obvious formation pressure and more usage. The three-stage casing head is usually used in high pressure deep well or exploration well;

2. According to the structure of the casing hanger.

The structure type of the casing hanger can be divided into the slip casing head, the core shaft type (threaded) casing head, the integral type (welding) sleeve head;

3. Interontological connection.

According to the connection mode of the body, it can be divided into flanged casing head, caliper casing head, and independent thread type (the casing head with thread connecting the upper end of the casing string and the lower end of the tubing head);

4. According to the structure of the body.

According to the structure type of the body, the monomer sleeve head (a hanger is installed in the body), and the combined casing head (a plurality of hanger in the body);

R&T Group offers casing hangers, which can be sorted into thread (mandrel) type and slip type. Slip casing hanger includes G type, W type, WD type, WE type and etc.

The number of casing layers can be divided into: single-stage casing head, double-stage casing head and three-stage casing head; The single-stage casing head is usually used in low-pressure shallow stratum production well; The double-stage casing head is suitable for the area with more obvious formation pressure and more usage. The three-stage casing head is usually used in high pressure deep well or exploration well;

|

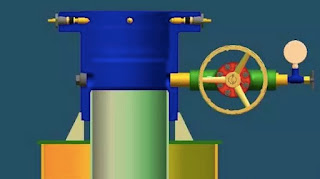

| SINGLE STAGE CASING HEAD |

|

| DOUBLE STAGE CASING HEAD |

|

| THREE STAGES CASING HEAD |

The structure type of the casing hanger can be divided into the slip casing head, the core shaft type (threaded) casing head, the integral type (welding) sleeve head;

3. Interontological connection.

According to the connection mode of the body, it can be divided into flanged casing head, caliper casing head, and independent thread type (the casing head with thread connecting the upper end of the casing string and the lower end of the tubing head);

4. According to the structure of the body.

According to the structure type of the body, the monomer sleeve head (a hanger is installed in the body), and the combined casing head (a plurality of hanger in the body);

R&T Group offers casing hangers, which can be sorted into thread (mandrel) type and slip type. Slip casing hanger includes G type, W type, WD type, WE type and etc.

Comments

Post a Comment