Casing head structure and sealing

As one of the biggest wellhead equipment manufacturers, Shengli oilfield and R&T group offers high quality casing head for sale.

1. Structure of wellhead casing head.

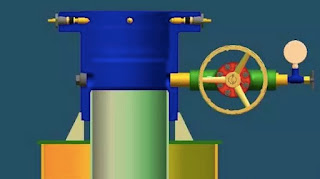

The casing head consists of casing head spool, casing hanger, top wire assembly, flange type parallel gate valve, connecting piece, pressure display mechanism, etc.

2. Rubber seal working principle.

Casing head seal consists of casing head ontology, BT type rubber sealing ring, casing hanger, dovetail rubber sealing ring, the top silk v-shaped sealing ring, sealing ring gasket, casing hanger hanging in casing head on the steps of ontology, as a result of the casing hanging heavy, metal to metal contact is passive seal rigidity, hanger and the casing pipe sealing for thread sealing.

Casing head spool has with the casing (or casing diameter) hanger diameter matching BT seal and corresponding greasing, pressure hole, must be from greasing valve sealing grease injection of high pressure, can make BT sealing effect. If the seal appears to be leaking, the grease valve and pressure valve should be injected into the seal to keep the seal in effect. The grease pressure does not exceed the rated working pressure of the flange; If the casing is sealed, it shall not exceed the rated allowable pressure of the casing. The pressure test hole is used for the outer seal test of the casing hanger.

There is a wire on the flange, which is used to lock the anti-wear sleeve (protective cover). After the casing hanger is present, the casing hanger can be locked. If there is leakage at the top, tighten the pressure cap to make the seal effective. Casing head cross on both sides of the flange, end plate valve (or blind flange), the other end of the plate valve, threaded flange, joint, cut-off valve and pressure gauge, pressure gauge can be observed and the annulus between the two layer casing pressure.

3. Metal and rubber seal of casing head.

Casing head metal, rubber seal consists of casing head ontology, BT type rubber sealing ring and the metal sealing components, metal sealing components, under the casing hanger, dovetail rubber sealing ring, the top silk v-shaped sealing ring, sealing ring gasket, casing hanger hanging in casing head on the steps of ontology, as a result of the casing hanging heavy, rigid passive seal metal to metal contact occurs. The casing hanger and casing are sealed with thread seal (see above); Metal sealing ring is installed on the flange on the former, by measuring the positions of the metal seal ring on the flange hole size, to determine the thickness of the adjusting ring, the adjusting ring on the flange hole of a certain amount of interference. When the upper flange and the casing head are connected, the ring is compressed through the casing head, so that the upper metal sealing ring is deformed to achieve the effect of the seal casing hanger.

Casing hanger under the metal sealing principle of sealing components, is through the metal seal ring and the casing head cross, the design of the casing hanger, ensure the geometric size of each part, using the 45 ° on the top wire cone rotation, make the metal sealing components under downward pressure ring, metal ring components u-shaped ring deformation, so, reach the role of sealing casing hanger.

R&T group offers wellhead assembly and wellhead components manufacturer.

1. Structure of wellhead casing head.

The casing head consists of casing head spool, casing hanger, top wire assembly, flange type parallel gate valve, connecting piece, pressure display mechanism, etc.

2. Rubber seal working principle.

Casing head seal consists of casing head ontology, BT type rubber sealing ring, casing hanger, dovetail rubber sealing ring, the top silk v-shaped sealing ring, sealing ring gasket, casing hanger hanging in casing head on the steps of ontology, as a result of the casing hanging heavy, metal to metal contact is passive seal rigidity, hanger and the casing pipe sealing for thread sealing.

Casing head spool has with the casing (or casing diameter) hanger diameter matching BT seal and corresponding greasing, pressure hole, must be from greasing valve sealing grease injection of high pressure, can make BT sealing effect. If the seal appears to be leaking, the grease valve and pressure valve should be injected into the seal to keep the seal in effect. The grease pressure does not exceed the rated working pressure of the flange; If the casing is sealed, it shall not exceed the rated allowable pressure of the casing. The pressure test hole is used for the outer seal test of the casing hanger.

There is a wire on the flange, which is used to lock the anti-wear sleeve (protective cover). After the casing hanger is present, the casing hanger can be locked. If there is leakage at the top, tighten the pressure cap to make the seal effective. Casing head cross on both sides of the flange, end plate valve (or blind flange), the other end of the plate valve, threaded flange, joint, cut-off valve and pressure gauge, pressure gauge can be observed and the annulus between the two layer casing pressure.

|

| casing head structure |

Casing head metal, rubber seal consists of casing head ontology, BT type rubber sealing ring and the metal sealing components, metal sealing components, under the casing hanger, dovetail rubber sealing ring, the top silk v-shaped sealing ring, sealing ring gasket, casing hanger hanging in casing head on the steps of ontology, as a result of the casing hanging heavy, rigid passive seal metal to metal contact occurs. The casing hanger and casing are sealed with thread seal (see above); Metal sealing ring is installed on the flange on the former, by measuring the positions of the metal seal ring on the flange hole size, to determine the thickness of the adjusting ring, the adjusting ring on the flange hole of a certain amount of interference. When the upper flange and the casing head are connected, the ring is compressed through the casing head, so that the upper metal sealing ring is deformed to achieve the effect of the seal casing hanger.

Casing hanger under the metal sealing principle of sealing components, is through the metal seal ring and the casing head cross, the design of the casing hanger, ensure the geometric size of each part, using the 45 ° on the top wire cone rotation, make the metal sealing components under downward pressure ring, metal ring components u-shaped ring deformation, so, reach the role of sealing casing hanger.

|

| casing head metal, rubber sealing |

Comments

Post a Comment