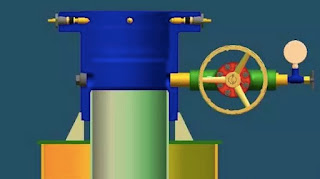

Oil Recovery Equipment Series From R&T Group

Our company was specialized in research, design, manufacture and service of Oil Recovery Equipment. Products include pumping unit, sucker rod, polish rod and sucker rod pumping. Our products and service have been used in more than twenty countries and regions, including America, Canada, Mexico, Germany, Australia, India, Indonesia, Saudi Arabia, Colombia, Kuwait, Russia, Kazakhstan, and so on. By the cooperation with famous companies, we have become the specialized manufacturing company, owning the independent intellectual property.

In strict compliance with ISO 9001 quality system standard, we have been equipped with advanced inspection equipment. Each link from raw materials processing to production process is strictly operated; with well-qualified quality inspectors and perfect testing equipment effectively controlling the whole production process and ensuring quality complied. Scientific design, compact structure and reasonable arrangement make onsite maintenance, parts replacement, installation and dismantle much easier. Our products are suitable for high temperature, sand and other special heavy oil well and super heavy oil, and successfully solves the problems of the exploitation for super heavy oil.

Specification of our Oil Recovery Equipment

Items of Oil Recovery Equipment

- Pumping unit: designed and manufactured in accordance with API 11E.

- Sucker rod: an essential part in the rod production system, is used to connect the pumping unit on the ground and the oil well pump down in the well.

- Polish rod: is widely used in hardware kitchen utensil and appliances, shipping, petrochemical industry, machine industry, medicine.

- Sucker rod pumping: can be run into oil tube with the sucker rod as an integer and it is not necessary to lift the tubing string when serving the pump.

- Oil Recovery Equipment Series for Sale

Pumping Unit

1. Designed and manufactured in accordance with API 11E.

2. Provide conventional beam pumping unit and all kinds of unconventional pumping unit (Dual Horsehead pumping unit, belt pumping unit, etc.).

3. Modular design has the advantages of reasonable structure, stable operation, low noise, convenient operation and maintenance.

4. The brakes use holding type structure, equipped with a safety device, flexible operation, rapid braking, safe and reliable.

Sucker Rod

The sucker rod, an essential part in the rod production system, is used to connect the pumping unit on the ground and the oil well pump down in the well. Products comply with Specifications of Sucker Rods (API Spec 11B) and other related standards, and have acquired the authorization to use Official API Monogram. The company produces K, C, D or HL sucker rods with various specifications complying API's requirements.

Polished Rod

R&T has a team of skilled and experienced staff with excellent qualities. With advanced production equipment and technology, it has constantly been developing and making new products to meet the meet the needs of customers.

Sucker Rod Pumping

R&T Group has been certified by ISO 9001 Quality Management System, and licensed to use API certificate. The company has established a complete inspection system and apply entire–process–control and inspection, from raw materials, semi–finished products to finished product. Our Products have been distributed to USA, Canada, Romania and Indonesia and Indonesia ect..

Comments

Post a Comment