Manifold Manufacturer---R&T Group

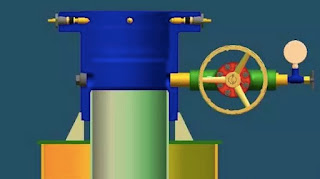

Our company is a professional manifold manufacturer. Products include fracturing manifold, choke & kill manifold, mud manifold, multifunction test manifold and annular manifold. With scientific and standardized management, the company owns an elite team who is dedicated and has strong technical and practical experience. We will continue to provide our customers with the best quality, the most competitive price, the best service, and as per the market demand, we will offer personalized value – added service and from the competitive advantage in direct supply and reliable supplier and partner in China. We are looking forward to a long – term friendly cooperation with you to achieve common development and mutual benefit.

We have strong technical force, excellent technical equipment, advanced detection methods. We strict executive program requirements of ISO 9001 and API standard, to ensure the products in control from the whole process of design, manufacturing, inspect and service.

The manifold is matched with barrel choke valve that is required to be orifice choke valve in case of stop function being required.

Specification of our Manifold

Items of Manifold

- Choke and kill manifolds: are important good control equipment in balancing the pressure in near-balanced drilling wells during petroleum exploration.

- Fracturing manifold: is high-pressure manifold used in oil well fracturing operation.

- The mud manifold: is special equipment for drilling fluid in the collection delivered by drilling pump which is composed of drill floor and ground valve groups, rigid lines, flexible pipeline, mud valve and filter.

- Multifunction test manifold: is made up pf blowout unit and test unit.

- Annular manifold: is mainly used on high-pressure discharge pipeline, water pipeline, temporary liquid flow pipeline, well test pipeline, cement and circulation pipeline and other high-pressure flow pipelines, and the working pressure can reach 105MPa in the condition of low temperature.

- Manifold For Sale

- Choke & Kill Manifolds

- Choke and kill mainfolds are important well control equipments in balancing pressure in near – balanced drilling wells during petroleum exploration. Choke manifold controls the casing pressure and maintains the balance inside the well, the soft closing of the well is realized by relieving pressure and maintains the balance inside the well, the soft closing of the well is realized by relieving pressure through the choke valve, through which the casing pressure can directly blow out in order to protect the well.

- Fracturing Manifold

- Our Manifold are designed with API 6A and API 16C standards. Fracturing manifold is height pressure manifold used in oil well fracturing operation. Fracturing liquid with viscosity is injected to the bottom of oil well by HP pump of large displacement through fracturing manifold, which can make cracks in the oil formation to realize enhanced oil recovery.

Mud Manifold

The mud manifold is special equipment for drilling fluid in the collection delivered by drilling pump which is composed of drill floor and ground valve groups, rigid lines, flexible pipeline, mud valve and filter. R&T Group's mud manifold meets API SPEC 16C /6A standards.

Multi-function Test Manifold

Multifunction test manifold is made up of blowout unit and test unit. This manifold is used for recovering mud, blowout, test and kill by mean of control of each valve of manifold. The blowout unit adopts the type of the tubing communication with the casing that make up a positive and negative direction circulatory system, the test unit adopts the type of parallel connection that make the testing more safe and reliable as for sulfide and corrosion resistance.

Annular Manifold

R&T Group' s Annular manifold meet API 16C and is mainly used on high pressure discharge pipeline, water pipeline, temporary liquid flow pipeline, well test pipeline, cement and circulation pipeline and other high pressure flow pipeline, and the working pressure can reach 105MPa in the condition of low temperature. All the materials are in accordance with ASTM or GB standard. Acidic environment products are in accordance with NACE-MR0175.

Comments

Post a Comment