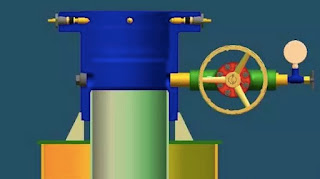

Ball Valve and Globe Valve

Ball Valve

Material: WCB、 WC6 、WC9、A105、 F11、 CF8、 CF8M

Material: WCB、 WC6 、WC9、A105、 F11、 CF8、 CF8M

Working pressure:CLASS150-CLASS1500

Nominal diameter:DN50-DN300

Temperature :-196℃-650℃

Connection type:flange, weld, thread

Suitable medium: water, oil, gas

Ball valve is mainly used to disconnect or connect the medium and can also be used to adjust and control the fluid. V type ball valve can carry out the relatively precise adjustment and control of flow volume, while three–way ball valve is used to dispatch the medium and change the flow direction of the medium. Compared with other types of valves, ball valve has the following advantages: The fluid resistance is small, and ball valve is the one which has the smallest fluid resistance among all types of valves, even the fluid resistance of the necking ball valves is quite small. The process of opening and closing is fast and convenient. As long as the valve stem rotates 90 degrees, the ball valve completes the total opening or closing action, which is easy to realize the fast opening and closing.

The structure design of elastic materials has been adopted for floating ball valve sealing ring. However, the structure design of the elastic float valve seat has been adopted for the trunnion mounted ball valve. It can be designed to have the sealing functions, such as fire–proof and anti–static–electricity. Full welding of the ball valve body can be directly in the ground, so that in case the valve from erosion and it is the ideal valve for oil and natural gas pipeline.

Globe Valve

1. Material: WCB、 WC6 、WC9、A105、 F11、 CF8、 CF8M

2. Working pressure:CLASS150-CLASS900

3. Nominal diameter:DN50-DN300

4. Temperature :-196℃-650℃

5. Connection type:flange , weld, thread

6. Suitable medium: water, oil, gas

The structure of globe valve is simpler than that of gate valve, and both its manufacturing and maintenance are relatively convenient.

The seal surface is not easy to wear and gall and has sound sealing performance. When being opened and closed, there is no relative slip between the valve flap and the seal surface of the valve, thus both the wear and gall are not severe and it has sound sealing performance and long service life.

When being opened and closed, the travel distance of the valve flap is small, thus the globe valve height is smaller than that of gate valve while the structure length is longer than that of gate valve.

When being opened and closed, the force torsion is large and it is laborious to open and close, and the time of opening and closing is relatively long. The fluid resistance is big because the medium channel in the valve is relatively tortuous. The fluid resistance and the power consumption are big.

When the nominal pressure of the medium flow direction PN ≦ 16MPa, downstream flowing is usually adopted and the medium flows upward from downward direction of the valve flap; when the nominal pressure PN ≧ 20 MPa, upstream flowing is usually adopted, and the medium flows downward from the upper direction of the valve flap. When being used, the globe valve medium could only flow in a single direction and the flow direction could not be changed.

The globe valve stem axis of the valve is perpendicular to the seal surface of valve seat. The opening or closing travel distance of the valve stem is relatively short and also it has the very reliable turning off action which enables this kind of value to be suitable for turning off the medium or functioning as adjustment and throttling.

Working pressure:CLASS150-CLASS1500

Nominal diameter:DN50-DN300

Temperature :-196℃-650℃

Connection type:flange, weld, thread

Suitable medium: water, oil, gas

Ball valve is mainly used to disconnect or connect the medium and can also be used to adjust and control the fluid. V type ball valve can carry out the relatively precise adjustment and control of flow volume, while three–way ball valve is used to dispatch the medium and change the flow direction of the medium. Compared with other types of valves, ball valve has the following advantages: The fluid resistance is small, and ball valve is the one which has the smallest fluid resistance among all types of valves, even the fluid resistance of the necking ball valves is quite small. The process of opening and closing is fast and convenient. As long as the valve stem rotates 90 degrees, the ball valve completes the total opening or closing action, which is easy to realize the fast opening and closing.

The structure design of elastic materials has been adopted for floating ball valve sealing ring. However, the structure design of the elastic float valve seat has been adopted for the trunnion mounted ball valve. It can be designed to have the sealing functions, such as fire–proof and anti–static–electricity. Full welding of the ball valve body can be directly in the ground, so that in case the valve from erosion and it is the ideal valve for oil and natural gas pipeline.

Globe Valve

2. Working pressure:CLASS150-CLASS900

3. Nominal diameter:DN50-DN300

4. Temperature :-196℃-650℃

5. Connection type:flange , weld, thread

6. Suitable medium: water, oil, gas

The structure of globe valve is simpler than that of gate valve, and both its manufacturing and maintenance are relatively convenient.

The seal surface is not easy to wear and gall and has sound sealing performance. When being opened and closed, there is no relative slip between the valve flap and the seal surface of the valve, thus both the wear and gall are not severe and it has sound sealing performance and long service life.

When being opened and closed, the travel distance of the valve flap is small, thus the globe valve height is smaller than that of gate valve while the structure length is longer than that of gate valve.

When being opened and closed, the force torsion is large and it is laborious to open and close, and the time of opening and closing is relatively long. The fluid resistance is big because the medium channel in the valve is relatively tortuous. The fluid resistance and the power consumption are big.

When the nominal pressure of the medium flow direction PN ≦ 16MPa, downstream flowing is usually adopted and the medium flows upward from downward direction of the valve flap; when the nominal pressure PN ≧ 20 MPa, upstream flowing is usually adopted, and the medium flows downward from the upper direction of the valve flap. When being used, the globe valve medium could only flow in a single direction and the flow direction could not be changed.

The globe valve stem axis of the valve is perpendicular to the seal surface of valve seat. The opening or closing travel distance of the valve stem is relatively short and also it has the very reliable turning off action which enables this kind of value to be suitable for turning off the medium or functioning as adjustment and throttling.

Comments

Post a Comment